Scientific Bulletin – Automotive Series

Scientific Bulletin – Automotive Series

Scientific Bulletin – Automotive Series

Scientific Bulletin – Automotive Series

Year XXXI, Volume 35

Robert Marian POPA, Adrian CLENCI, Victor IORGA-SIMĂN, Rodica NICULESCU

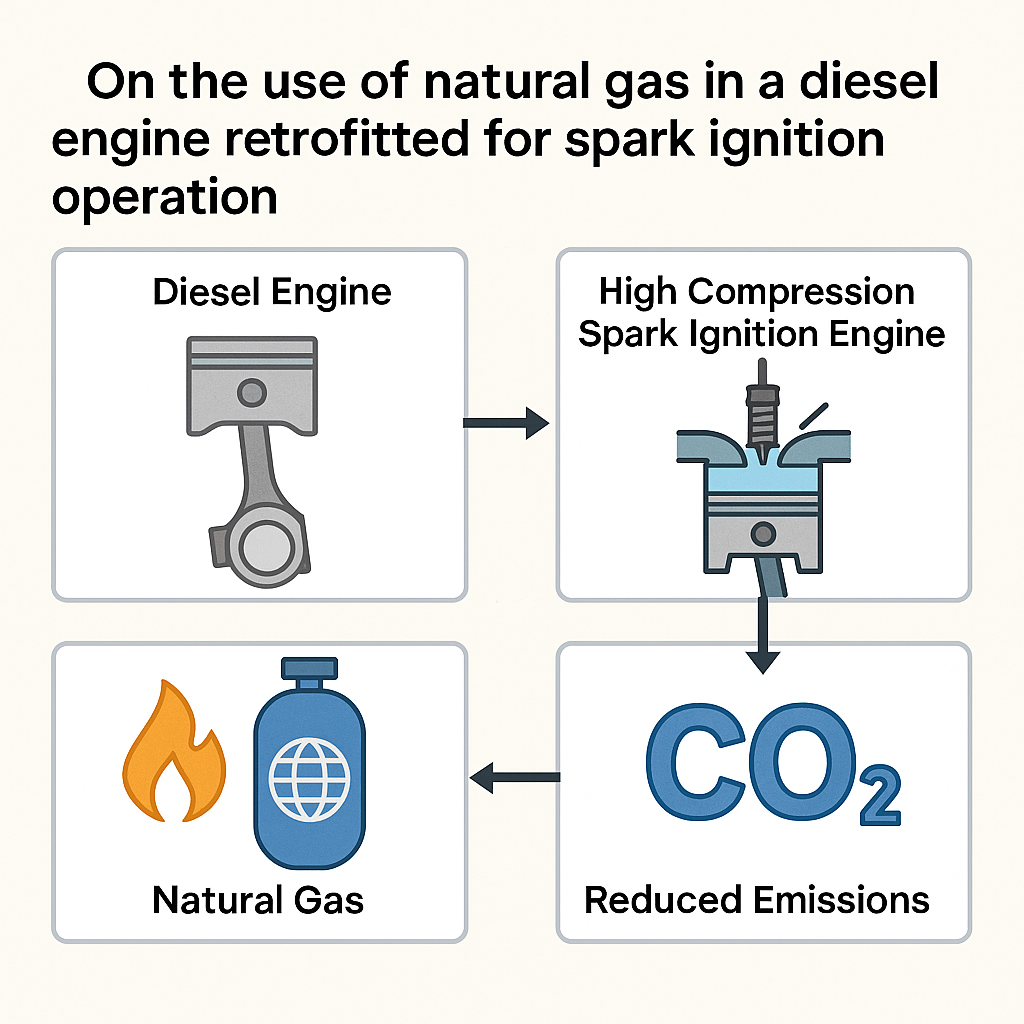

The problem of global warming is becoming an increasingly intense concern for all industries. In order to limit the increase in temperature to 1.5°C by 2030, according to the Paris agreement of 2015, humanity should reach zero CO2. Among the alternative fuels available now, methane gas is considered to be one of the best substitutes for fossil fuels.The main problem in using the methane gas as fuel is missing of an exclusive optimisation of the engines due to compromise in bi-fuel operations.The paper will present the engine prototype, its adaptation on a vehicle, aiming to be tested on the roller bench for emissions, as well as experimental results obtained at the engine test bed showing a comparison with a standard commercial gasoline engine.

Maria-Magdalena DICU, Daniel-Constantin ANGHEL

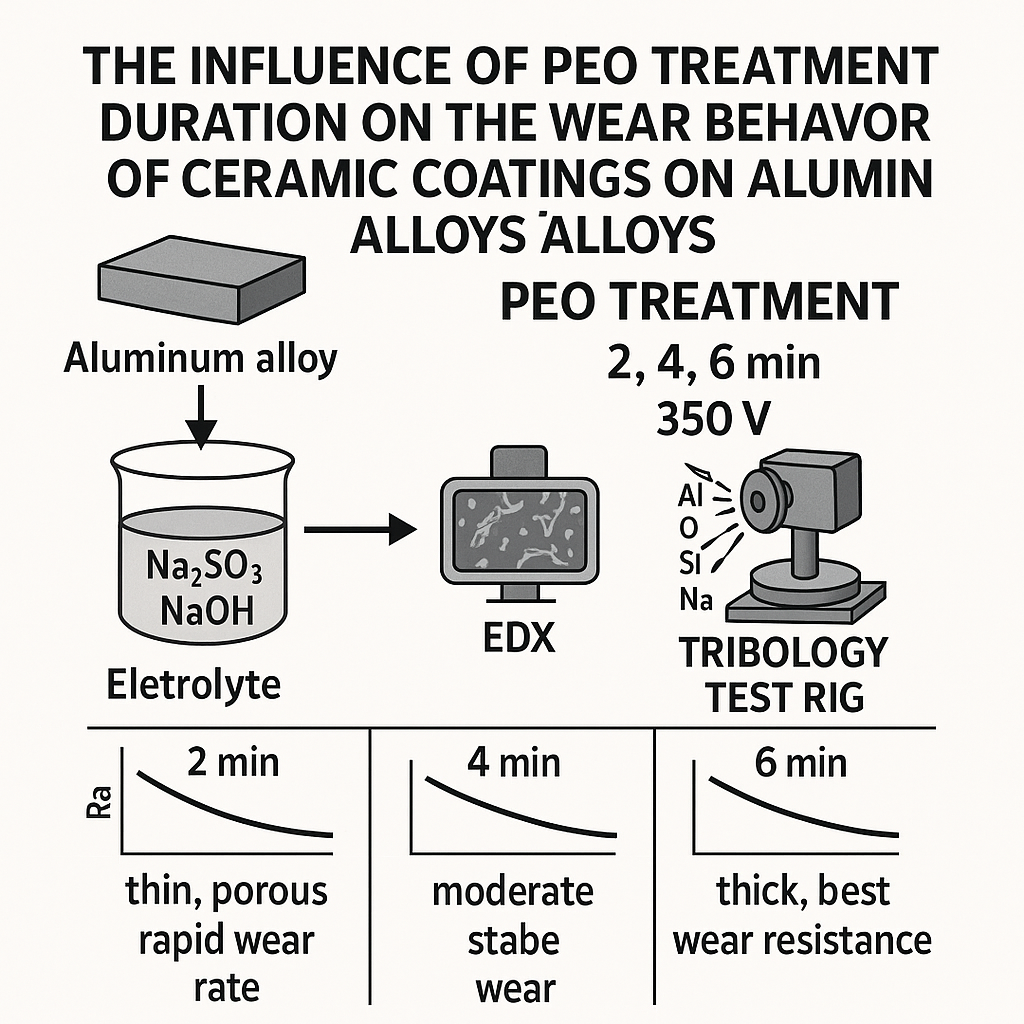

This paper presents the development and characterization of ceramic coatings obtained by Plasma Electrolytic Oxidation (PEO) on aluminum alloys. The electrolyte used is a mixture of sodium metasilicate (Na₂SiO₃) and sodium hydroxide (NaOH). The resulting surfaces were characterized using Scanning Electron Microscopy (SEM), Energy Dispersive X-ray Spectroscopy (EDX), and tribological testing. Additionally, correlations between structure and performance were discussed.

Razvan UNGUREANU, Andreea TINTATU

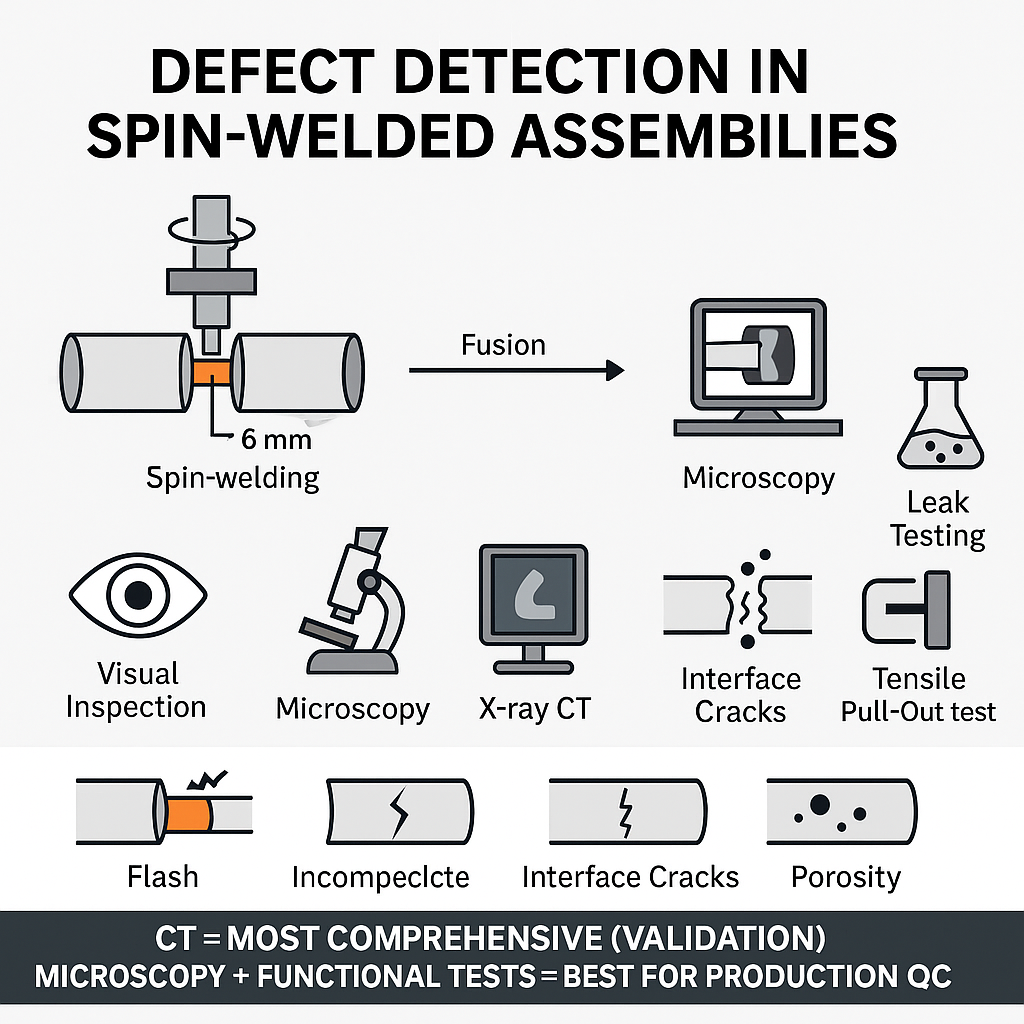

Spin Welding (SW) is a solid-state joining process widely used for thermoplastic components in automotive fluid transfer systems, offering high mechanical strength, sealing integrity, and full process traceability. However, due to the internal location of the weld interface, conventional optical inspection methods cannot be applied, making defect detection challenging. This study investigates defect detection and characterization in SW tube–connector assemblies, focusing on applications in safety-critical automotive environments. Assemblies were produced using a Mecasonic 72 horizontal SW machine, with process parameters established through Design of Experiments (DOE). A comprehensive evaluation methodology was applied, combining external visual inspection, bright field and polarized light microscopy, X-ray computed tomography (CT), leak testing, and tensile pull-out testing. The analysis identified common defect types, including flash formation, incomplete fusion, interface cracks, and porosity, and correlated their occurrence with deviations in welding time, displacement, and energy input. CT scanning proved most effective for complete circumferential defect mapping, while a combination of bright field microscopy and functional tests was deemed more practical for production environments. The findings provide a technical foundation for subsequent optimization of SW process parameters to reduce or eliminate defect occurrence.

Razvan UNGUREANU, Andreea TINTATU

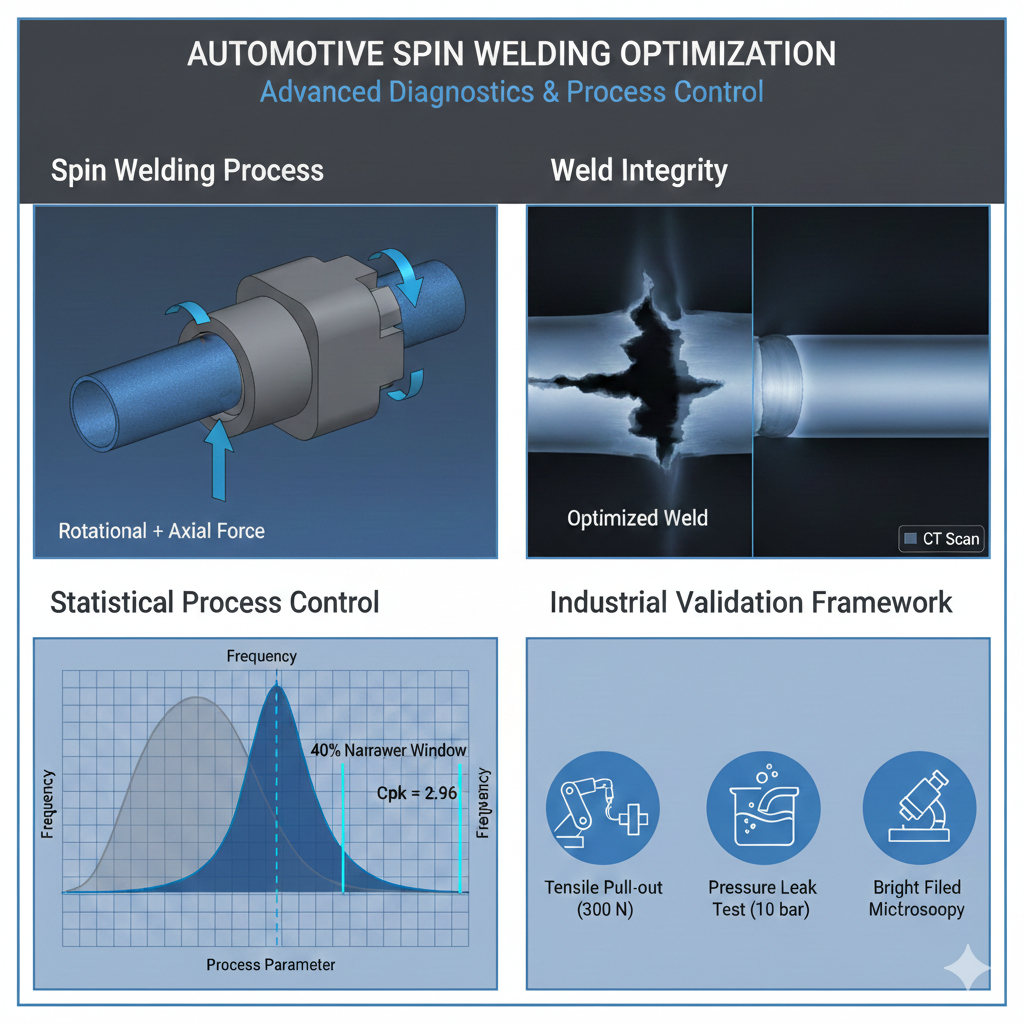

Abstract:Ensuring the integrity of thermoplastic tube–connector joints is essential for the reliability and safety of automotive fluid transfer systems. This work focuses on defining and optimizing spin welding parameters to minimize defect occurrence and guarantee consistent joint quality. A Design of Experiments (DOE) approach was applied on a Mecasonic 72 horizontal welding machine, testing 20 parameter sets across 200 assemblies. Results showed that only 25% of the initial parameter sets fulfilled all acceptance criteria, underlining the narrowness of the unoptimized process window. To address this, Taguchi’s loss function was combined with statistical capability studies (Cp, Cpk) performed on 100 production samples, leading to optimized parameter ranges with tolerance intervals reduced by nearly 40%. The optimized process demonstrated high robustness, with capability indices significantly above automotive requirements (Cpk ≥ 1.67). Validation through tensile pull-out tests, leak testing, and light microscopy confirmed the elimination of defects such as incomplete fusion, excessive flash, and cracks. The proposed framework provides a reliable methodology for achieving defect-free spin-welded joints, offering both statistical rigor and industrial feasibility for large-scale automotive production.